I love creating free content full of tips for my readers, you. I don't accept paid sponsorships, my opinion is my own, but if you find my recommendations helpful and you end up buying something you like through one of my links, I could earn a commission at no extra cost to you. Learn more

A lot of people out there are tired of failing at soldering copper pipes. Butane torch might be an unorthodox solution, but it works miracles when it comes to soldering copper pipes. You’ll even find many industries as incumbent to this technique.

We’ll be guiding you in every step of the way, just tag along.

In this post we'll cover:

- Mini Torch for Soldering Copper Pipe

- How to Solder Copper Pipe With a Butane Torch/Lighter

- Soldering a 2-Inch Copper Pipe

- Preparation of the Copper Pipe

- The Preparation of Pieces for Joining

- Removal of the Burrs

- Sanding

- Cleaning Before Application of the Flux

- Application of Flux Layer

- Preparation of The Butane Torch

- Filling The Butane Torch

- Turning on the Torch

- The Use of Flame

- Soldering the Joints on the Copper Pipes

- Proper Cleaning of the Joint

- How to Solder Old Copper Pipe

- How to Solder Copper Pipe Without Flux

- How to Silver Solder Copper Pipe

- FAQ

- Conclusion

Mini Torch for Soldering Copper Pipe

The soldering process requires the torch to be heated up. But you will see that the mini torches do not get heated as much as the usual torches get. So the question arises whether it is possible to solder copper pipe with a mini torch? The answer is, yes. You can solder the copper pipes with the mini torch but it will take more time than a usual torch. Again, it is more efficient for soldering smaller pipes. It is very precise and is very light in weight which makes it easy to carry.

How to Solder Copper Pipe With a Butane Torch/Lighter

A butane torch (like one of these top choices) is a very handy tool to aid in soldering copper pipes. It can solder the copper pipes to great precision.

Soldering a 2-Inch Copper Pipe

The soldering of a 2-inch copper pipe is a very common task to be done in the manufacturing industries. The steps to be followed for this are as follows:

Preparation of the Copper Pipe

The preparation of the copper pipe indicates the tasks to be done before the soldering to be started on the pieces to be joined. The steps are as follows:

The Preparation of Pieces for Joining

First of all, you need to cut the pipes with the help of a pipe cutter. The cutter is to be set into place with a depth of 2-inch. By every four spins on it, the knob is tightened to precision. The process is to be repeated until the pipe is cut. Surely this is never the way to solder copper pipes having water.

Removal of the Burrs

This is a vital task to do for getting a proper solder joint. Rough edges called burrs are produced when you cut the copper pipes into pieces. They need to be removed before soldering. With the help of a deburring tool, you need to remove these burrs

Sanding

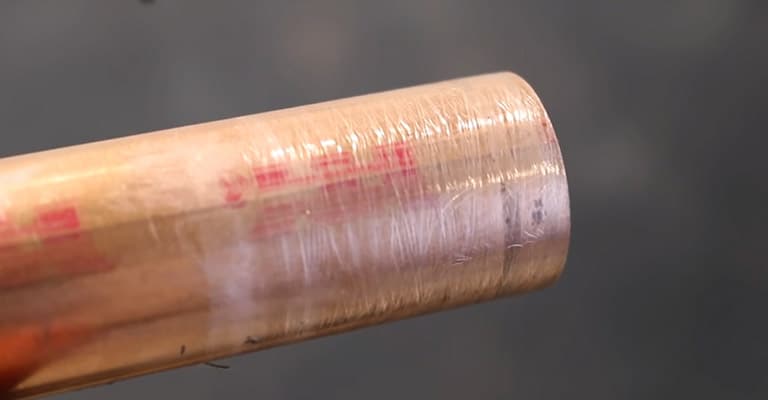

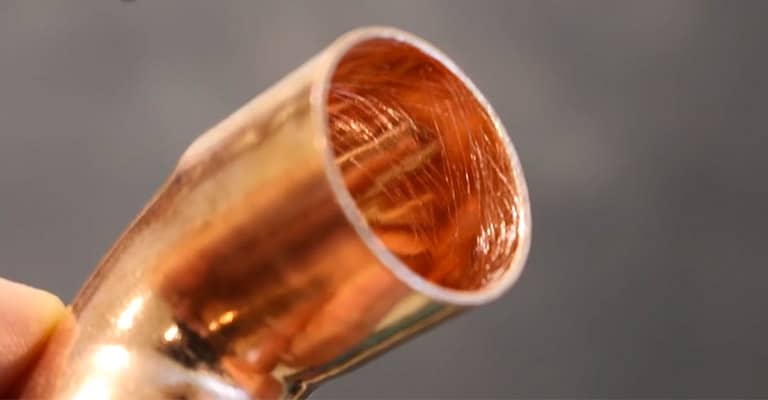

Take the abrasive material as per your choice and sufficient sand. Then you need to sand the inside area of the fittings and the outside area of the pipes.

Cleaning Before Application of the Flux

Before the flux to be applied, you need to wipe off the excess sand or any dirt on the pieces with a wet rag.

Application of Flux Layer

Once the sanding operation is completely done, you need to apply flux to the inner area of the fittings and the outer area of the pipes. Flux removes the oxidation that took place on the metals and helps the soldering paste to flow thoroughly. Capillary action helps the soldering paste to adhere and flow to the heat source and along the way, fills up the gaps with flux.

Preparation of The Butane Torch

This step indicates the preparation needed to be taken for the butane torch to be used in the soldering process. The steps are as follows:

Filling The Butane Torch

Firstly, you need to catch hold of the torch and butane canister and then you have to go outside. Make sure that you have sufficient ventilation when you are filling the torch. Then you need to remove the cap from the butane filled bottle. At this point, turn the torch upside down and a filling point will be visible from the bottom of the torch. Then the tip of the butane canister needs to be pressed and thus, butane will flow to the torch.

Turning on the Torch

Your workspace should be covered with a fireproofing surface before turning on the torch. The head of the torch needs to be pointed about 10 to 12 inches above the surface at an angle measuring 45 degrees and then the torch needs to be turned on by starting the butane flow and a click on the ignition button.

The Use of Flame

The outer flame is a dark blue flame with a transparent appearance. The inner one is an opaque flame and the lightest one between the two. “Sweet spot” indicates the hottest part of the flame which is just in front of the lighter flame. This spot should be used to melt the metal quickly and help the solder to flow.

Soldering the Joints on the Copper Pipes

You need to heat the joint with the heat produced by the butane torch for about 25 seconds. When you notice that the joint has reached the perfect temperature, the soldering wire is to be touched with the joint. The solder will get melted and will be sucked into the joint. When you notice the melted solder to pour out and dripping, you need to stop the soldering process.

Proper Cleaning of the Joint

How to Solder Old Copper Pipe

Soldering the old copper pipes will require the removal of dirt and the corrosive layer on them. A paste-like solution using white vinegar, baking soda, and salt should be prepared taking equal parts of each should be prepared. Then it is to be applied to the corroded areas of the pipes. After 20 minutes, you need to wipe off the solution properly and thus the pipes are made corrosion-free. Then, as usual, the process of soldering copper pipe is to be followed to solder the old copper pipe.

How to Solder Copper Pipe Without Flux

Flux is one of the most vital components in soldering copper pipes. Soldering without flux can get tough as the pieces will not join perfectly. But even if the flux is not used, soldering can be done. You can use a solution of vinegar and salt to use instead of flux. It will go perfectly into the joints when soldering is done especially on copper.

How to Silver Solder Copper Pipe

Silver soldering on copper pipe or brazing is a very important process in the manufacturing world. Brazed joints are strong, ductile and the process is an economical one. The process of silver soldering copper pipe is described below:

FAQ

Q: Can I silver solder with a propane torch? Ans: There remains the possibility of heat loss when propane torch is used for silver soldering. You can silver solder with a propane torch but you have to make sure that the heat loss to the atmosphere and the parts is lower than the heat which is being put into the soldering joint. Q: Why cleaning of the pieces of pipes is important before the application of the flux? Ans: Cleaning of the pieces of the copper pipes is important because if they are not cleaned properly, the flux cannot be applied to the pieces properly. If you apply flux on a pipe with dirt, the soldering will be hampered. Q: Do the butane torches explode? Ans: Since butane is a highly flammable gas and it is kept in the torch under huge pressure, it can explode. Butane has caused injuries or even killed people when it is used incorrectly. You should be aware of the harmful effects of it and take safety measures while using it.Conclusion

Soldering since its advent has added a whole new dimension to the manufacturing world especially in the sector of mounting and joining of the materials. Butane torches or the micro torches are nowadays found appropriate in using while soldering the copper pipes. This has brought a new degree in the copper soldering with its high efficiency. As an enthusiast on soldering, technician or anyone who wants to learn to solder, this knowledge of soldering copper with butane torches is a must.I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.